Maximizing Your Productivity with a Professional Factory Fit-Out

Factory fit-outs are vital to maximizing business productivity and efficiency. This guide will walk you through the stages of planning, designing, installing, and maintaining a professional factory fit-out to elevate your business operations and provide a safer working environment.

- Defining a Factory Fit-Out

- Importance of a Professional Factory Fit-Out

- Benefits of a Professional Factory Fit-Out

- Stage 1: Planning

- Stage 2: Space Analysis

- Stage 3: Design and Layout

- Stage 4: Installation and Commissioning

- Stage 5: Ongoing Monitoring and Maintenance

- Benefits of a Professional Factory Fit-Out

Defining a Factory Fit-Out

A factory fit-out involves the analysis, planning, and execution of enhancements to a factory facility’s physical makeup. These enhancements can serve to optimize the use of available space, improve workflow, and increase productivity.

Importance of a Professional Factory Fit-Out

A factory fit-out is an investment in your business’s success, providing a platform for growth, increasing your operational efficiency, and improving profitability. A professional factory fit-out will ensure that your factory is optimized to run optimally from day one.

Benefits of a Professional Factory Fit-Out

The benefits of a professional factory fit-out extend beyond just financial returns. They also include:

- Improved safety measures

- Smart space utilization, including the addition of extra storage space

- Enhanced quality assurance systems

- Increased employee productivity and satisfaction

Now let’s dive into the stages of a professional fit-out process.

Stage 1: Planning

The planning stage is the foundation of the factory fit-out project. During this stage, you should:

Define Your Needs and Objectives

Outline your goals and objectives for your factory and determine how enhanced functionality and efficiency will help you achieve them.

Budget Allocation

You need to define your budget, allowing you to work within your financial means while avoiding any unexpected expenses that may arise.

Project Timeline

It’s important to create a project timeline that outlines each project stage’s timeframe to ensure that it’s running on schedule.

Stage 2: Space Analysis

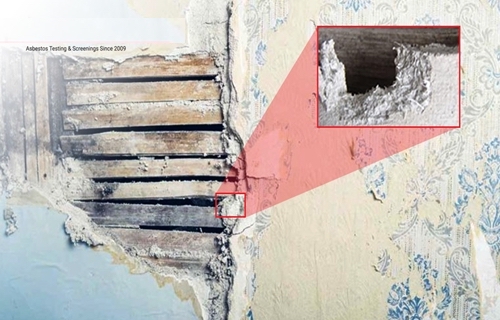

The space analysis phase requires a comprehensive evaluation of the existing factory space to identify operational bottlenecks and suggest improvements to the existing layout.

Factory Space Assessment

Review the space requirements, giving consideration to the production line, storage areas, and workstation locations, among others.

Identifying Operational Bottlenecks

Identify inefficiencies in your current workflow and areas that require adjustments and strategic re-organization.

Recommendations for Layout and Design

Receive recommendations for layout and design modifications that will best configure the space, improve workflow, and enhance operational efficiency.

Stage 3: Design and Layout

The design and layout stage builds upon the space analysis results and aims to enhance the space’s functionality and optimize workflow.

Smart Space Utilization

Maximize the use of the existing space available by ensuring that every part of the factory is utilized to its full potential.

Workflow Optimization

Create workflows that minimize motion and improve production efficiency.

Introducing Quality Assurance Systems

Introduce quality assurance systems adhering to quality and operational guidelines, eliminate obsolete equipment and technology, and lower energy costs.

Mezzanine and Storage Solutions for Additional Space

Integrate mezzanine floor storage solutions or redesign the existing facility storage solutions, ideas to add or expand existing space to increase productivity.

Stage 4: Installation and Commissioning

With design and layout completions, the next phase in the factory fit-out project involves installation and commissioning.

Project Management

Ensure that the project manager oversees a competent team, who are experts in equipment and facility installation.

Safety Regulations and Standards Compliance

Adhere to strict safety regulations and standards during installation to ensure that both employees and visitors are safe.

Equipment and Component Quality Assurance

Use only premium and well-established equipment and components to guarantee maximum efficiency, longevity, and performance.

Commissioning Testing

Perform comprehensive initial testing of every aspect of the factory operations after installation and commissioning.

Stage 5: Ongoing Monitoring and Maintenance

As your factory runs, it’s essential to keep track of progress, identify any potential hitches, and come up with solutions.

Regular Inspection and Maintenance

Regular inspection and maintenance are necessary to ensure that the factory’s infrastructure and equipment is in good working order and repairs are addressed before they escalate into significant issues.

Incorporating Feedback

Incorporate employee feedback to meet their needs and improve employee productivity and comfort.

Keeping up with Technological Advancements

Technology is continually advancing, and keeping up with new trends, equipment, and software can help a factory run more efficiently.

Benefits of a Professional Factory Fit-Out

A professional factory fit-out provides various benefits for your business, including:

Increased Operational Efficiency

A new layout and optimized workflow can streamline operations and improve worker productivity, resulting in cost savings, reduced downtime, and improved quality output.

Improved Safety Standards

A well-designed and executed factory fit-out can significantly increase safety levels, reduce the risk of employee injuries, and mitigate production losses due to accidents.

Space Optimization and Cost Savings

Through strategic planning and design, available space is optimized, which can save cost and increase space utilization.

Increased Employee Morale and Productivity

A new factory fit-out can improve the working environment and employee morale, resulting in increased productivity and job satisfaction.

To read more about this topic, check out previous blog post at How to Improve Workflow with a Warehouse Fit-Out: A Step-by-Step Guide

For more general information on building then please visit: https://www.building.vic.gov.au/

A professional factory fit-out enhances the production process, increases efficiencies, ensures employee safety, and offers substantial returns on your investment. Take your time in planning, keep your eye on the timeline and budget, and be meticulous in the execution. As long as you consistently assess the factory and maintain oversight of the project, you’ll get all the benefits a professionally executed factory fit-out can offer.